Is the traditional KPI dead? The future of performance management in a data-driven era

By Felipe Cruz, Global Solutions Leader, Actionable Insights

In the automotive industry, Key Performance Indicators (KPIs) have long been used as essential tools in measuring success. They offer a clear, albeit limited historical view of a company’s performance. However, as the industry evolves and embraces digital transformation, and data becomes more abundant, is relying solely on retrospective metrics enough to remain competitive?

Forward-looking analytics, real-time data integration, and predictive models are becoming increasingly critical. These tools can provide deeper insights into customer behavior, market trends, and operational efficiencies, enabling companies to not just track past performance, but also anticipate future challenges and opportunities, thereby driving proactive decision-making and innovation.

Revolutionizing performance measurement

Traditional KPIs tend to be reactive, providing information on what occurred without delving into the reasons behind it or suggesting preventive measures. In a data-driven world, predictive and prescriptive models can help transform how performance is measured and managed. By leveraging data to forecast future outcomes and suggest actions, OEMs can increase the complexity of their business decisions, enhancing their predictive and prescriptive capabilities. Unlike KPIs, which provide a static view of past performance, predictive models use advanced algorithms and machine learning to analyze vast amounts of data, uncovering patterns and correlations that might not be immediately obvious.

This shift from reactive to proactive analytics is crucial for staying competitive in a fast-paced industry. Let’s look at a few examples of how this approach can transform operations, reducing costs, enhancing efficiency and improving satisfaction.

Fleet management optimization

For a company managing a large fleet of delivery vehicles, traditional KPIs might track breakdowns or maintenance costs. But predictive models analyze maintenance records, repair history, and performance data, allowing them to forecast optimal maintenance intervals and suggest preemptive part replacements. By analyzing patterns in vehicle performance data, manufacturers and mobility players can identify the most common causes of breakdowns and forecast when these issues are likely to occur, meaning they can schedule maintenance before problems arise. This proactive approach not only improves operational efficiency but also extends the lifespan of the fleet while reducing downtime and lowering maintenance costs.

Dealer network strategy

Optimizing dealer networks is another area where predictive models excel. Traditional methods might consider geographic coverage and sales data. However, predictive models incorporate variables like demographic data, buying habits, and local competition. They can consider factors such as income levels, commuting patterns, and competitor locations to simulate various scenarios and recommend the best locations for new dealerships, maximizing market coverage and sales potential. This strategic placement ensures that dealerships are positioned to capture the maximum market share and serve the highest number of potential customers.

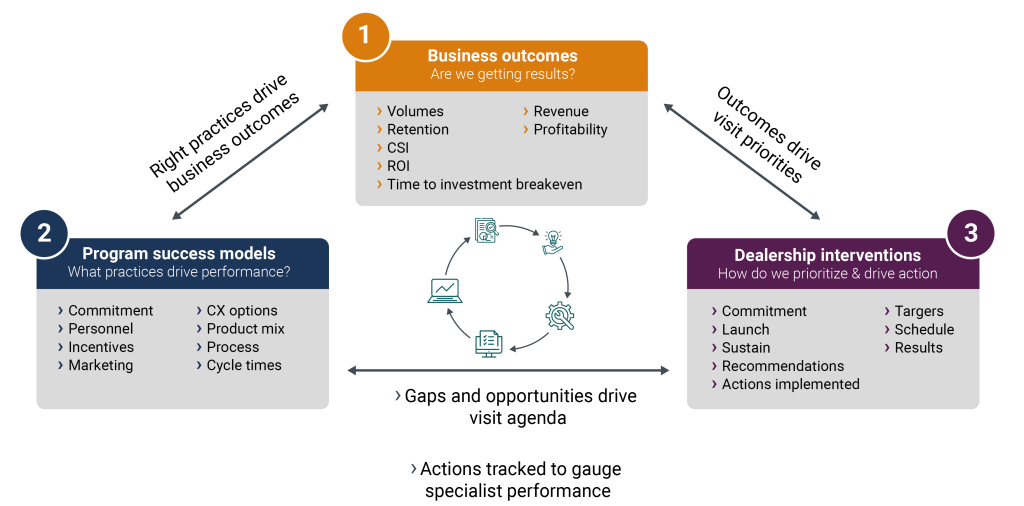

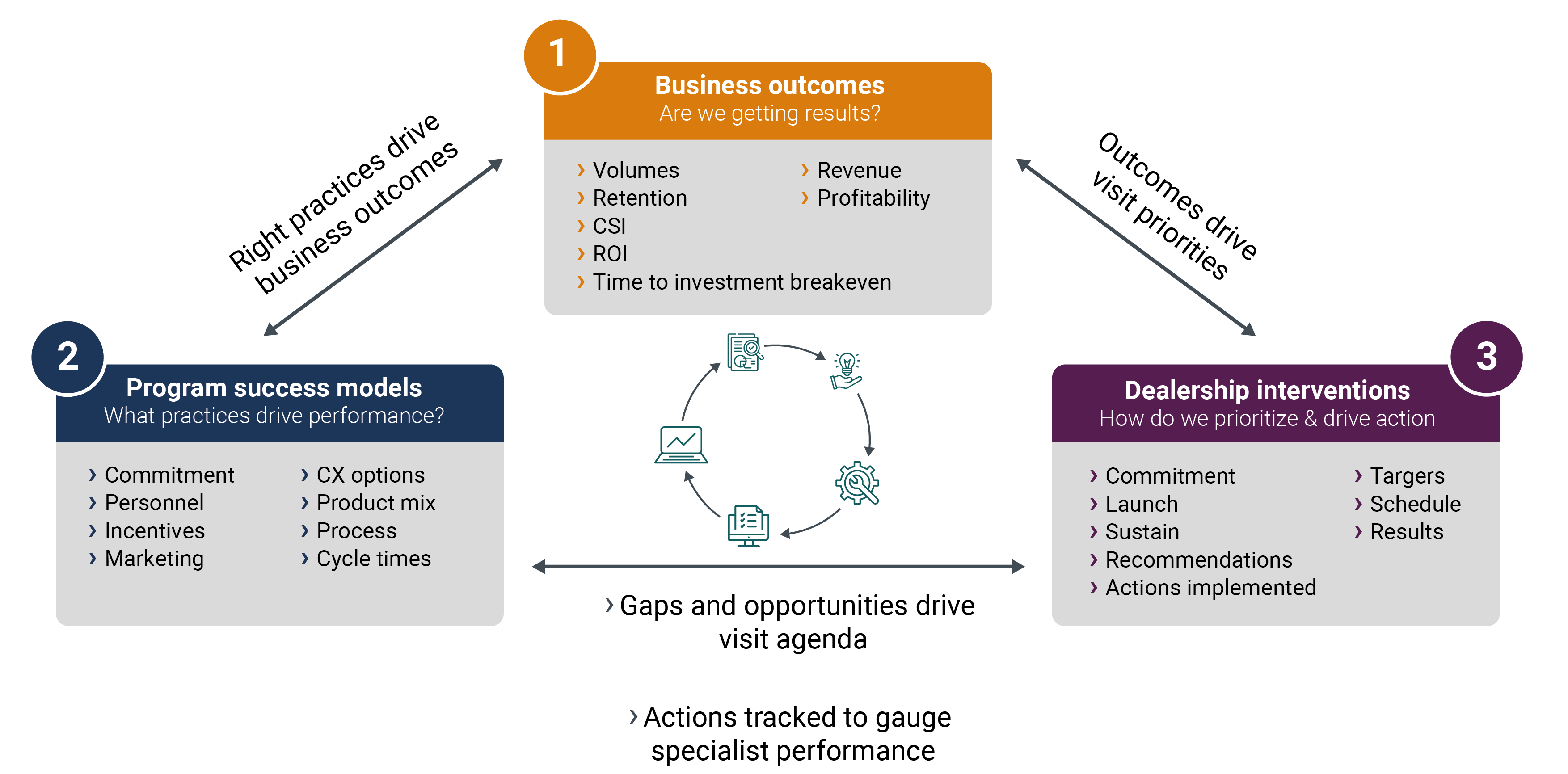

Data-driven field programs

With a multitude of field consultants, coaches, and specialists visiting and supporting dealerships across the globe, MSX allows for a bi-directional interaction where we collect data and provide support where and when it is necessary. In most cases, support is provided in the form of an action plan for implementation by dealership personnel. After years offering support and analyzing operational and financial data, we have developed a success model that clearly links actions to desired outcomes. We can identify the actions needed to improve specific KPIs and create scalable, tailored plans for our customer’s network. This is only possible by combining field-collected data with the operational and financial data provided by our customers. Our approach integrates advanced data science models and proven human expertise, offering a unique optimization strategy that includes perspectives and dimensions often overlooked by customers.

The power of combined expertise

Successfully implementing predictive models in the automotive industry requires a deep understanding of automotive systems, processes, and customer behaviors. Combining data science with automotive expertise ensures that models are accurate and actionable, providing real-world value.

While a data scientist might develop a robust predictive model, an automotive expert can provide the necessary context to interpret the results and apply them effectively. This collaboration bridges the gap between theoretical insights and practical application, ensuring that predictive models deliver tangible benefits.

Automotive experts can refine predictive model recommendations by considering specific operating conditions and practical constraints. This combined expertise ensures that the predictive model’s insights are practical and actionable.

Adapting KPIs for the future

The question isn’t whether KPIs are needed anymore, but how they can evolve to stay relevant. In this rapidly changing industry, leveraging live, constantly evolving data for proactive decision-making is essential. Retail networks require dynamic and comprehensive solutions that harness this real-time data, providing insights that drive continuous improvement and sustainable growth. By adopting these models, manufacturers and mobility players can optimize operations, enhance customer experiences, and gain a competitive edge. KPIs are not dead—they’re becoming part of a more sophisticated approach to measuring and driving success.

Integrating predictive models and advanced analytics is the next frontier in performance measurement. Those who adapt and utilize the power of live data will be the ones who thrive.